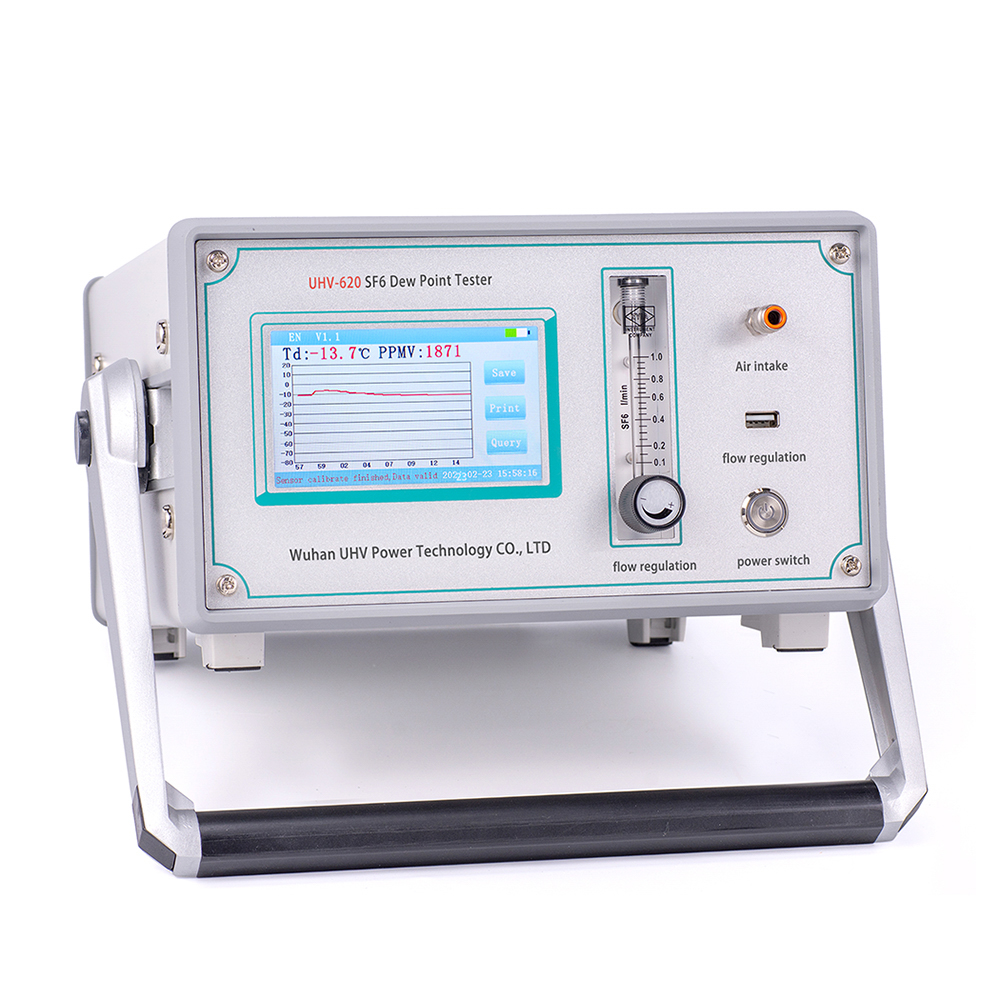

Өнім Parameters:

The intelligent micro water measuring instrument is a precision instrument specifically designed for accurately measuring the trace moisture content in gases, especially insulation gases such as sulfur hexafluoride commonly used in high-voltage electrical equipment. It has a wide range of applications in fields such as power, chemical, steel, electronics, and scientific research, especially in the safety monitoring and maintenance of power systems.

Technique Parameters:

| Өлшеу диапазоны | Dew point value:-80℃~+20℃ |

| Moisture content:0~19999uL/L | |

| Accuracy of measurement | ±1.0℃(-60℃~+20℃) |

| ±2.0℃(-80℃~-60℃) | |

| шешімі | Dew point value: 0.1℃ |

| Moisture content: 1uL/L | |

| Response time(+20℃,0.1mpa) | 63% need 5s, 90% need 45s(-80℃~+20℃) |

| 63% need 10s,90% need 240s(+20℃~-80℃) | |

| Sampling flow | 0,6л/мин±20% |

| Қысым диапазоны | 0~1.0Mpa |

| The use of temperature | -20℃~+60℃ |

| Қоршаған ортаның ылғалдылығы | 0~100%RH |

| Зарядтау уақыты | 4 сағат |

| The whole machine size | 250×150×300mm3 |

| The weight of The machine | 4.4kg |

Ерекшелігі:

High precision and sensitivity: capable of detecting trace amounts of moisture at the ppm or even ppb level.

Quick response: The response time of modern intelligent instruments has been greatly reduced.

Portability: Many models are designed to be portable for easy on-site testing.

Data traceability: Storing and exporting data facilitates quality management and fault analysis.

Easy to operate: Intelligent design reduces the threshold for operation.

Safe and reliable: Accurate monitoring helps prevent equipment failures and safety accidents.

Main application scenarios:

1. Power system:

Handover test, preventive test, and fault diagnosis of SF6 electrical equipment (GIS combination devices, circuit breakers, transformers, bushings, etc.).

Monitor the moisture content in SF6 gas to prevent insulation performance degradation caused by excessive moisture, corrosion of equipment by arc decomposition products, and freezing at low temperatures, ensuring the safe operation of the power grid.

Acceptance of SF6 new gas, monitoring of filling process, and treatment of recovered gas.

2. Other fields:

Semiconductor manufacturing: Moisture monitoring of high-purity process gases such as nitrogen, argon, and hydrogen.

Chemical production: moisture control of reaction gases, protective gases, carrier gases, etc.

Compressed air system: detects dew point in compressed air to prevent pipeline corrosion, instrument failure, and product moisture.

Lithium battery production: Dew point monitoring of inert gases (such as argon) in drying rooms and glove boxes.

Pharmaceutical industry: moisture control for special gases and packaging environments.

Research: Various experiments that require precise control or measurement of gas humidity.