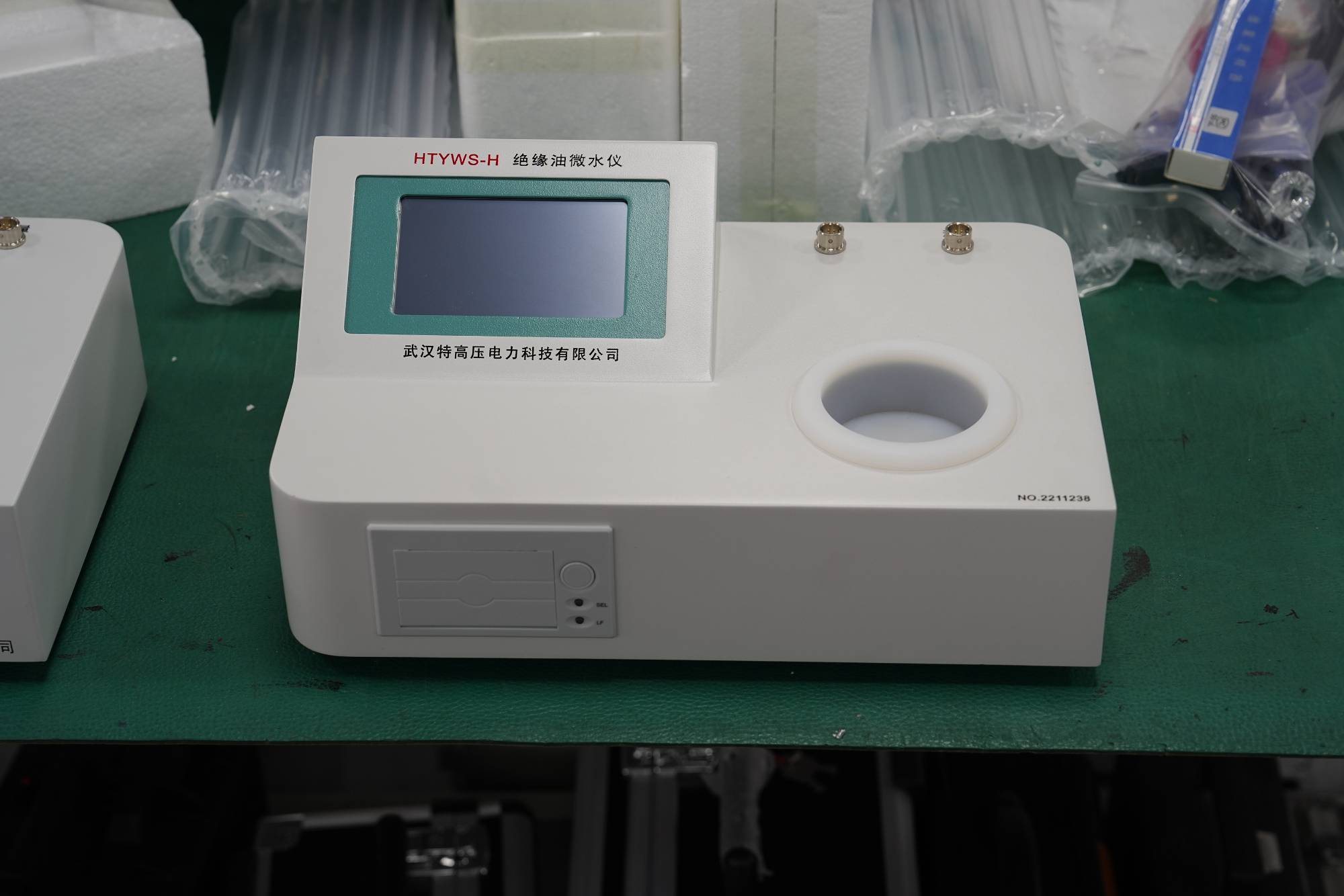

The trace moisture analyzerunder UHV power can help many power workers conduct various power tests more conveniently.

Karl Fischer titration is an advanced desktop chemical method that can accurately measure the water concentration in various sample types. It is highly praised for its ability to distinguish water over the widest possible range; Reduce from 100% to 100 parts per million. The application scope of Karl Fischer test has expanded accordingly.

How is Karl Fischer titration performed

Karl Fischer titration follows one of two easily replicable processes: Coulombic titration or volumetric titration. The two are mainly similar. Firstly, combine the sample of interest with an anodic solution that promotes oxidation. This solution typically contains alcohol base, sulfur dioxide (SO2), and homogeneous halogens such as pyridine.

Immerse the platinum cathode into a battery filled with anode solution and induce current. The cathode consumes sulfur dioxide and produces iodine (I2), which then undergoes a stoichiometric reaction with water. Usually, one mole of iodine is consumed per mole of water. The second electrode detects the voltage difference to provide accurate electrochemical readings of water content.

The endpoint of Karl Fischer titration is mainly the difference between Coulomb titration and volumetric titration. In the Coulombic determination of moisture content, percentages are determined by electrochemical methods. In the volumetric method, you will determine the endpoint through the potentiometric method.

The recognized application of Karl Fischer titration method

The Karl Fischer titration method can be said to be the most reliable and accurate moisture content testing method, covering a wide range of application fields. This is a brief choice:

Clothing and textile manufacturers using wool, silk, and cotton typically use Karl Fischer titration to identify unwanted moisture and remove any signs of moisture that may cause damage to the material.

Wood and paper producers with vested interests in controlling moisture content also rely on this test to eliminate large amounts of this substance.

Even in the construction industry, applications can be seen where the strength and durability of building materials such as cement largely depend on the perfect mixing of materials to achieve an appropriate balance of consistency in concrete manufacturing.